https://www.pentech.us/wp-content/uploads/2016/04/MG-Spray-Gun-feat-img.jpg

1000

1500

projects@coldspringdesign.com

https://www.pentech.us/wp-content/uploads/2023/11/Pentech-Logo.svg

projects@coldspringdesign.com2016-04-01 11:35:512023-11-29 22:25:11MG Spray Gun Exploded View

https://www.pentech.us/wp-content/uploads/2016/04/MG-Spray-Gun-feat-img.jpg

1000

1500

projects@coldspringdesign.com

https://www.pentech.us/wp-content/uploads/2023/11/Pentech-Logo.svg

projects@coldspringdesign.com2016-04-01 11:35:512023-11-29 22:25:11MG Spray Gun Exploded View https://www.pentech.us/wp-content/uploads/2016/04/MG-Spray-Gun-feat-img.jpg

1000

1500

projects@coldspringdesign.com

https://www.pentech.us/wp-content/uploads/2023/11/Pentech-Logo.svg

projects@coldspringdesign.com2016-04-01 11:35:512023-11-29 22:25:11MG Spray Gun Exploded View

https://www.pentech.us/wp-content/uploads/2016/04/MG-Spray-Gun-feat-img.jpg

1000

1500

projects@coldspringdesign.com

https://www.pentech.us/wp-content/uploads/2023/11/Pentech-Logo.svg

projects@coldspringdesign.com2016-04-01 11:35:512023-11-29 22:25:11MG Spray Gun Exploded View

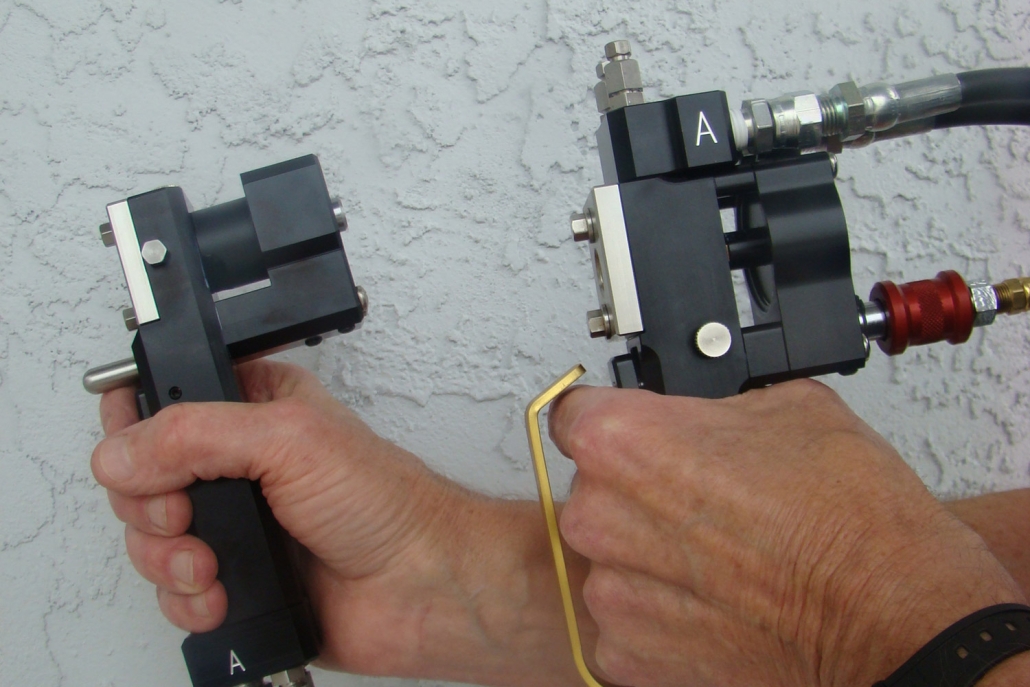

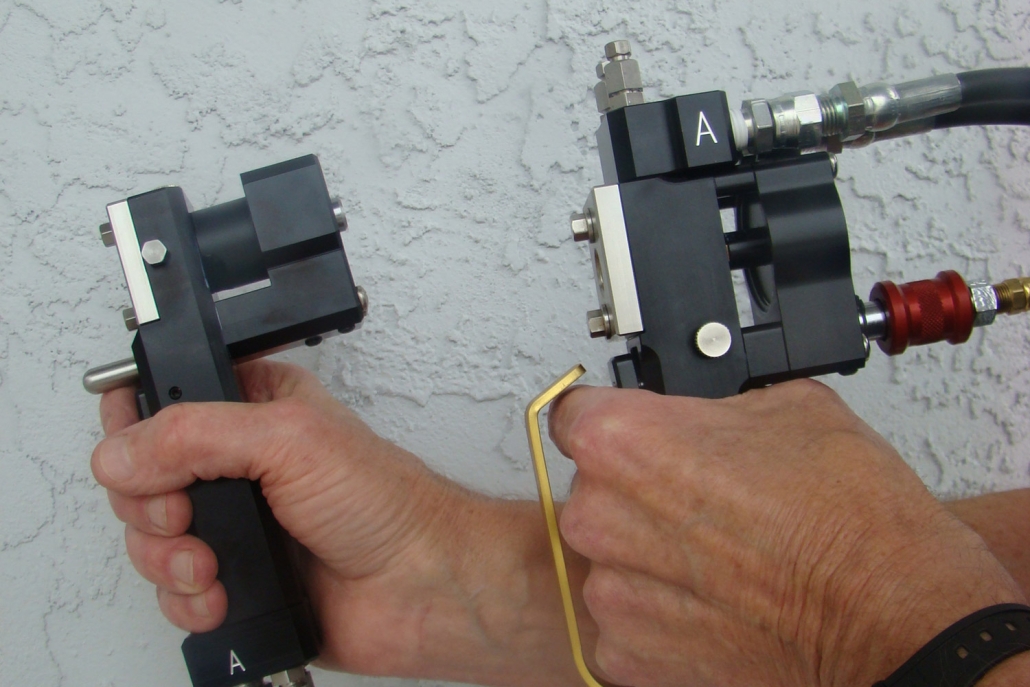

Spray Non Skid in Action

Recently we received some photos of the Pentech S6MM Non-Skid…

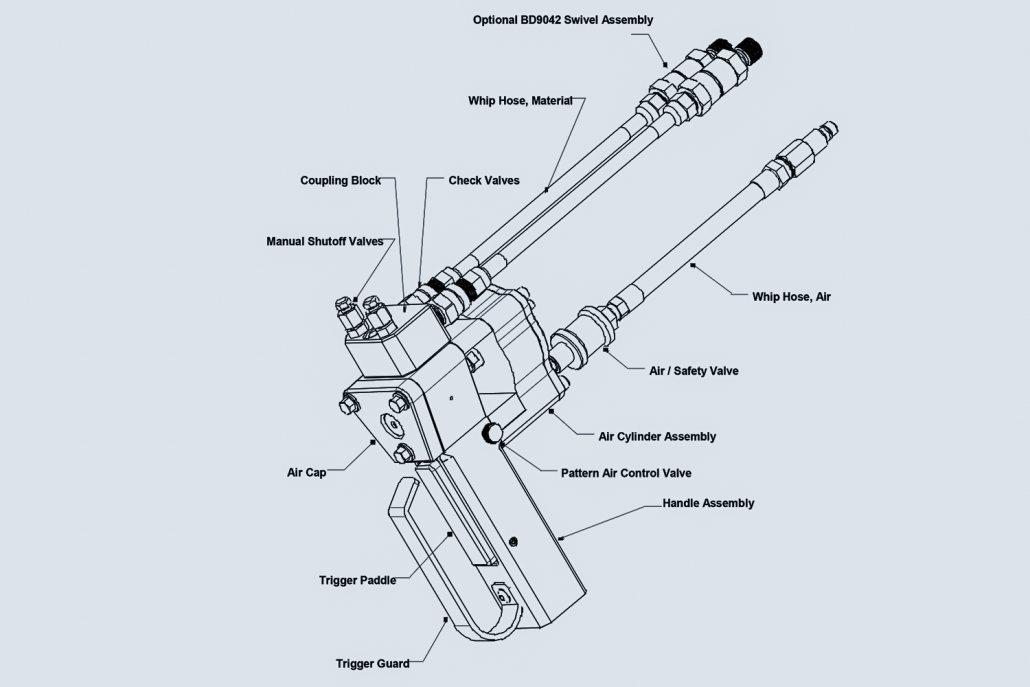

Reintroducing the BD Gun

High Pressure, Plural Component, Direct Impingement, Mechanical…

Sprayable Non-Skid Equipment

Non-skid deck coatings in the past have typically been roll…

Pentech Announces Commercial Release of Non-Skid Spraying Systems

The Pentech S6MM and VS3MM Series of non-skid spray systems…